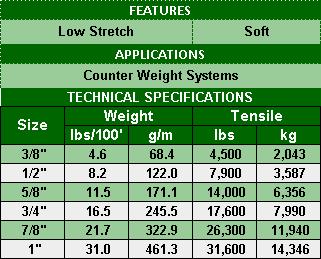

Stage-Set X Stage Rope

Patented parallel fiber core design results in a very round, firm rope with no stretch perfect for counterweight systems where a rope that bounces can make setting lines more difficult. Spun fiber in the cover makes this rope easy to handle.

Sunlight/UV:

Very little degradation from sunlight. Can be used outside over long term if inspected regularly.

Chemicals:

Polyester has good resistance to most chemicals, except 95% sulfuric acid and strong alkalines at boil.

Heat:

Polyester melts at 480°F with progressive strength loss above 300°F.

Dielectrics:

Good resistance to the passage of electrical current. However, dirt, surface contaminants, water entrapment, and the like can significantly affect dielectric properties. Extreme caution should be exercised any time a rope is in the proximity of live circuits.

Sheaves:

Recommended sheave diameter to rope diameter is 8:1.

Working Loads:

No blanket safe working load (SWL) recommendations can be made for any line because SWL's must be calculated based on application, conditions of use, and potential danger to personnel among other considerations. It is recommended that the end user establish working loads and safety factors based on best practices established by the end user's industry; by professional judgment and personal experience; and after thorough assessment of all risks. The SWL is a guideline for the use of a rope in good condition for non-critical applications and should be reduced where life, limb, or valuable property is involved, or in cases of exceptional service such as shock loading, sustained loading, severe vibration, etc. The Cordage Institute specifies that the SWL of a rope shall be determined by dividing the Minimum Tensile Strength of the rope by a safety factor. The safety factor ranges from 5 to 12 for non-critical uses and is typically set at 15 for life lines.